Here at Exhibit Studio + Westwind Design, we love a good challenge and pride ourselves on taking display solutions to the next level. Innovation is core to who we are, and we’re thrilled to launch a cutting-edge display panel product that not only stands out, but also stands the test of time and wear.

We’re excited to introduce Fortex Dye-Sublimated Panels: A Premium dye-sublimated graphics panel system with exceptional vibrance, versatility, and durability.

Keep reading to discover why we’re so excited about Fortex and its applications within the print and display industry!

What Is Dye Sublimation?

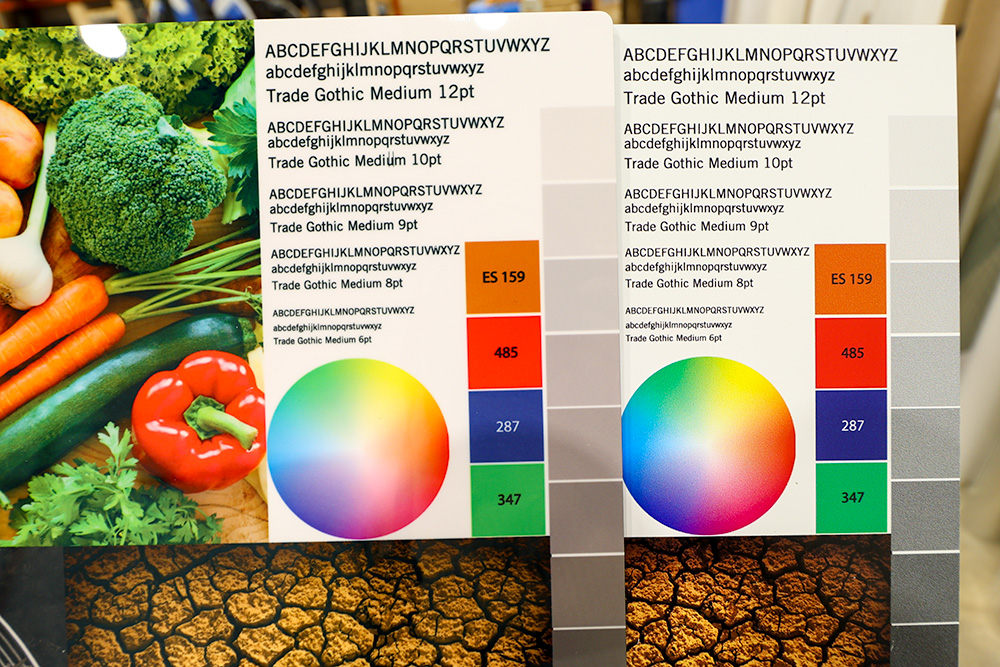

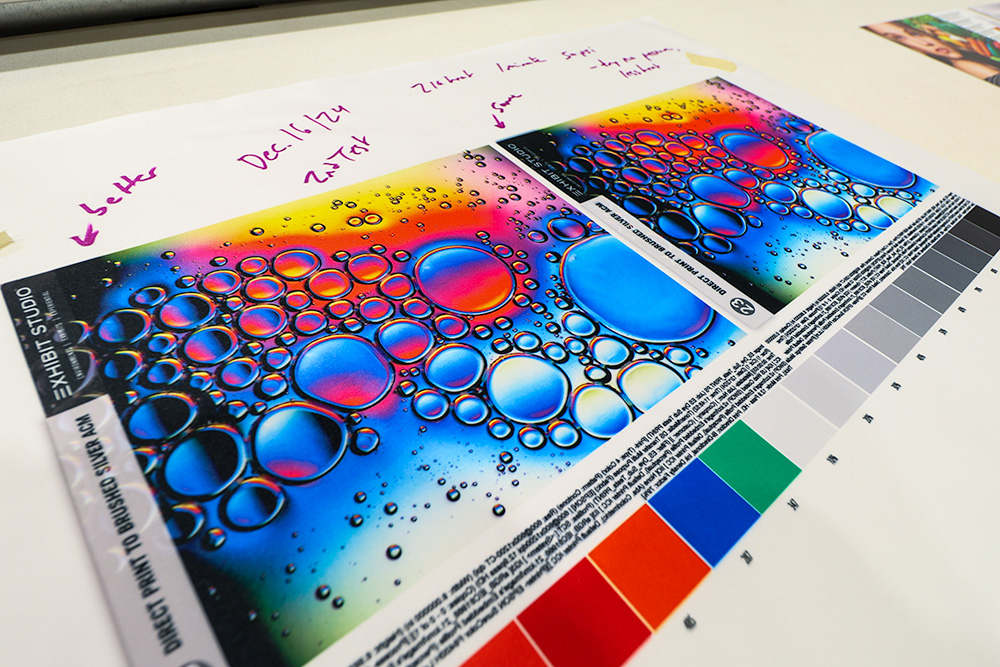

Dye-sublimation printing is a powerful print process that vaporizes ink into a material for unparalleled durability and colour vibrancy. Unlike traditional printers that deposit layers of ink onto the surface of a material, dye sublimation alters the state of the ink with heat and pressure to permanently bond with the substrate.

What Makes Fortex Special?

Fortex panels feature custom-formulated layers of powder coating that allow the material to receive graphics fused directly into its surface. This powerful process results in vivid colours and unmatched durability. Fortex is a premier solution for indoor and outdoor branded environments, where durability and longevity are key.

We understand the frustrations of relying on foreign suppliers with limited options and lengthy turnaround times. That’s why we’re proud to be one of the only Canadian suppliers offering this specialized product. Our Calgary-based operation ensures local support, high-quality materials, and reliable solutions for clients across Canada and beyond.

The Powder-coating advantage

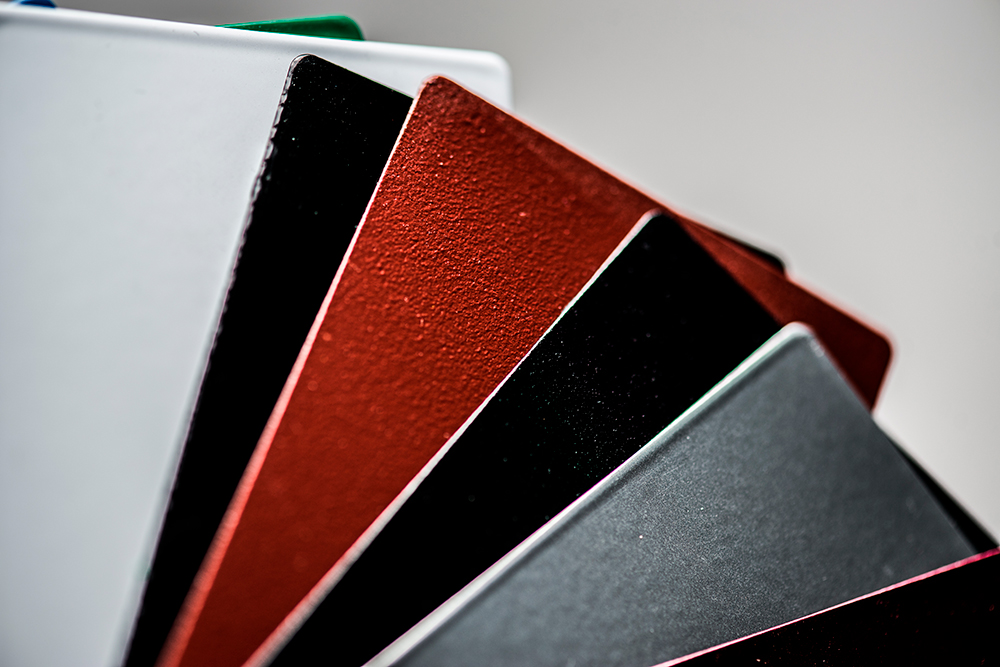

Powder coating is a key element that makes Fortex materials so effective. Unlike spray-painting, powder coating uses a dry powder activated by an electrostatic charge to adhere to the surface. The substrate is then heat-cured, transforming the coating into a tough, wear-resistant layer. This protective coating applied to high-quality anodized aluminum ensures that graphics panels are tougher than nails, while also being lightweight and aesthetically striking.

Powder coating is also incredibly efficient, reducing waste by 95% compared to traditional spray painting. The result? A consistent, durable finish that looks stunning and lasts for years!

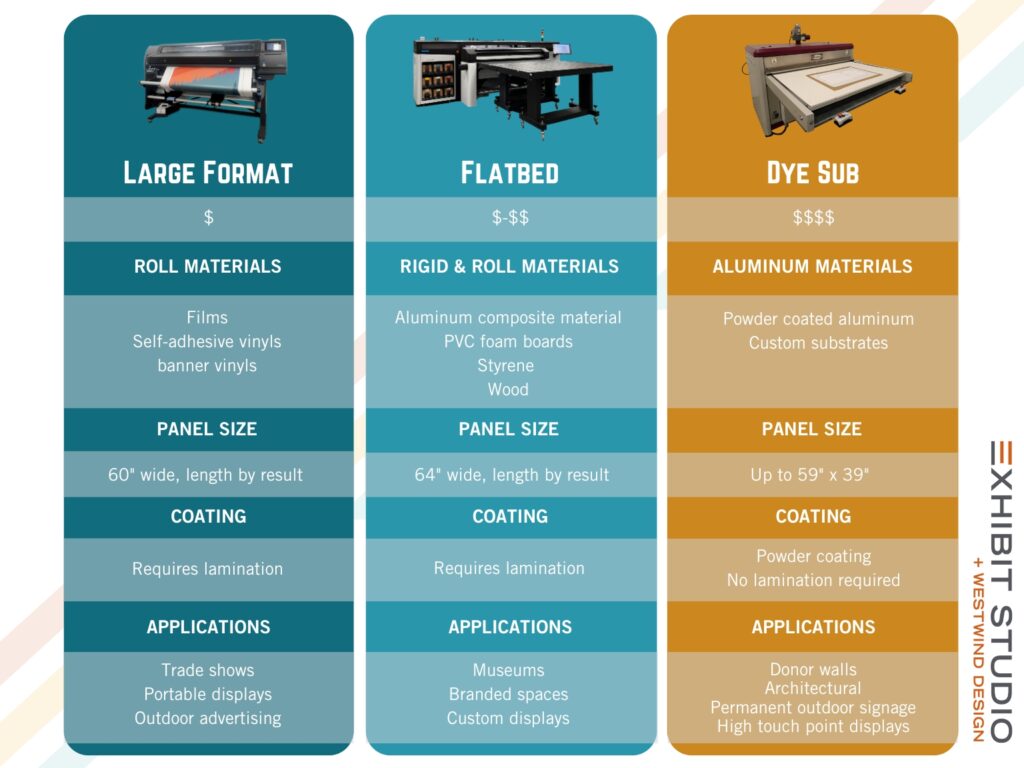

How Does Fortex Differ From Other Print Processes and Materials?

Our studio runs multiple different printers, each with their own benefits and applications. Take a glance below to see how it differs from other printing processes that we offer.

Benefits of Fortex Panels

Unmatched Durability

Fortex panels resist scratches, fading, and moisture, making them ideal for both indoor and outdoor use. They’re UV and fire-resistant, maintaining their vibrancy even in harsh conditions. These substrates will never peel, chip or flake.

Seamless Integration

Fortex panels can be directly mounted to walls for large-scale murals, wall art, or other visual displays with seamless results.

Versatility

Available in a variety of finishes, textures, and materials, Fortex panels can be frameless or framed. Currently we offer powder-coated aluminum substrates, with other custom options available. This can include textured tread as well as perforated panels.

Anti-Graffiti & Hospital-Grade Material

Fortex panels are perfect for high-traffic and high-touch point areas, offering chemical resistance for easy cleaning. Spray paint, permanent marker, and other stains wipe off effortlessly with standard cleaning products.

Fortex Key Features

- Indoor and Outdoor Applications: 9 different finishes for versatile use including matte, canvas, glossy—even glow in the dark!

- Outdoor Durability: 5-year outdoor warranty; vibrant colours even under intense sunlight.

- Bendable Design: Adaptable for unique, dimensional fabrications.

- Low Maintenance: Easy to sanitize and anti-graffiti.

- Exceptional Strength: Scratch, UV, and fire-resistant.

- Eco-Friendly: Water-based inks, recyclable materials, and VOC-free.

Why Choose Fortex?

As one of the only Canadian suppliers of powder-coated aluminum panels with dye-sublimated graphics, we’re excited to bring Fortex to the display industry. Whether you’re designing for museums, interpretive centres, architectural projects, or outdoor applications, Fortex panels deliver unmatched performance and aesthetic appeal with limitless possibilities unique to your brand and needs.

READY TO MAKE A visual IMPACT WITH Fortex?

Our team has worked tirelessly to develop the highest-quality aluminum dye-sub materials and print process, offering a premium versatile solution for various industries. Explore how Fortex Dye-Sublimated Panels can transform your next project into a durable, visually stunning masterpiece!