Crates are often an overlooked component for clients when it comes to trade show display considerations. If only we could shove everything in a box, nail it shut and wave “See ya!”. However, crates for modular and custom trade show displays require custom fabrication to effectively use the space and minimize shipping costs, while keeping everything organized and protected. Understanding the time, cost, and specifications for crates is an essential part of exhibiting that will help you stay within your budget and on time for your project.

Portable trade show displays come with ready-to-go options for shipping and transportation due to their pre-determined, standard sizing. When you decide to go with a modular or custom design, your unique booth will be constructed from a variety of frames, hardware, and graphic panels. Unlike portable graphic panels constructed from vinyl or fabric — which can roll up into compact transportation systems — modular and custom systems are sometimes hard-mounted to solid panelling such as ACM or Sintra. Aluminum frames such as Octanorm or Betmatrix are used to provide the framework for many modular styles of systems. While these have an extensive range of configurations, there are also standard lengths (typically 8ft long) for this hardware. Hence the need for a crate!

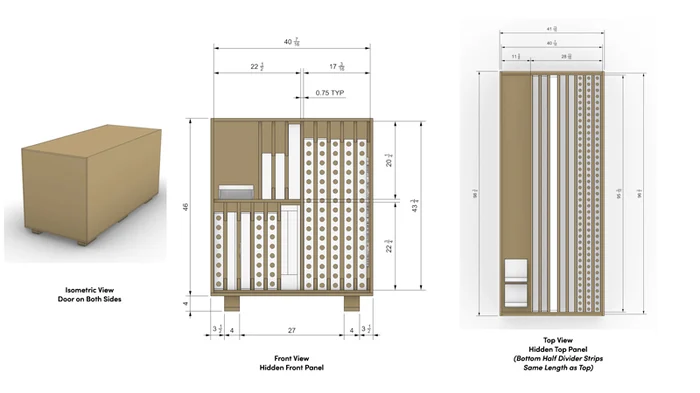

Crate Sizes & Design

Depending on your trade show display size and materials, crate sizes can vary. However, we always try to keep each crate under 4 feet wide, and 8 feet long (height can vary). Why’s that? When we ship out using carriers, two 4×8 crates can sit side by side. Any wider than 4 feet and additional costs could be incurred for shipping and handling, as well as for material handling at the trade show location. A larger size could also risk more damage during the handling process.

Crate sizes can be unique to every booth, depending on the materials and hardware, such as freestanding walls, countertops, spacers, etc. The first step in designing your crate is through our industrial design team. Modular and custom displays are designed and mocked up to scale using 3D software. This is for conceptual design; to get a detailed understanding of what the display will look like. It’s also for our team to create assembly instructions and design your crate. Once the display has been built and the parts are finalized, we design the crate in our 3D modelling software using Rhino or SolidWorks.

3D rendering of one of our crate designs

The designer’s first step in establishing the crate’s dimensions is to determine what the longest piece of material/hardware is. From there, it’s kind of like Tetris… The designer establishes what can go where within the crate, with standard tolerances and allowances. Typically it starts with allocating space for the vertically stacked panels and then building around that area. We use separators and compartments to maximize how everything fits efficiently.

Crate Fabrication

When it comes to fabrication, it typically takes a team of 1 – 2 anywhere from one to three days to build (depending on complexity). All crates are built from scratch! We don’t have just one standard crate design to avoid having any space that isn’t being used. Not only does this minimize shipping costs for our clients, but It also prevents the contents from shifting around during transport.

Plywood is used to build the crates, as a sturdy material that doesn’t add unnecessary weight to the cost of shipping. The crate build contains an inner “lip” on the bottom 2-3 inches into the crate. This is done for durability and shipping, to prevent the trim from ripping off with handling equipment.

We also build wooden “feet” underneath each crate. The main box rests on the feet to allow space for a pallet jack to get underneath. When a crate is under 37 inches narrow, the crate gets casters (wheels with brackets) instead of feet. This is because you can’t fit a pallet jack underneath. In that case, having the ability to roll the crate around is the best option. This can also save time and money for a crate this size; without wheels, you need a forklift which can cost more for handling at the trade show location.

Protecting Your Crate Contents

While some crates can be designed to stack all the components flat, we typically design to keep the panels and frames vertical. This ensures that graphics and any delicate components are kept in the best possible condition using spacers. That way we don’t risk damage from the weight being distributed horizontally through compaction. It also makes it easier for installers to take out the pieces and minimize any scratching or other damage. It keeps things organized and is designed for efficiency.

We add protective pieces on the bottom of the crate to prevent scratching. Additionally, carpet and felt fabric are used to protect different areas in the crate, depending on how sensitive they are (like a TV monitor for example).

Custom-built trade show display crates with various compartments and spacers

Once the crate is with the carrier, we have less control over the shipping and handling. An extra step that we often take is to add sensors inside the crates to tell whether the crates have been treated roughly during shipping or handling. If a crate is more top-heavy, we use a tip sensor. This is an irreversible sensor that tells whether a crate has fallen over. How does this work? It’s a fairly simple flat package attached to the inside; if it is tilted past a certain degree, the sensor area will change colour.

We also use G-force sensors, which are also able to tell if the crate was handled roughly in transit. This measure helps us with accountability during shipping and handling. It also assists with quality control; we can monitor and work with the best shipping and handling vendors possible for your display to arrive in top condition.

As you now know, crate design is an integral part of your trade show display to ensure everything arrives in the best possible condition. It is carefully designed to consider weight distribution, organization, handling, and protection. Layered spacers and compartments are essential to making sure the space is effective and not being wasted. Crates are a necessary custom solution that ensures you are minimizing your shipping and handling costs, and storing them as safely as possible.