When you’re planning your next trade show booth, one of the first decisions you’ll face is this: modular or custom? Both can look incredible and deliver results—but they’re built very differently behind the scenes.

The biggest difference comes down to the frame used to build the structure. Let’s break it down.

Modular Exhibit Frames: Flexible, Scalable, Smart

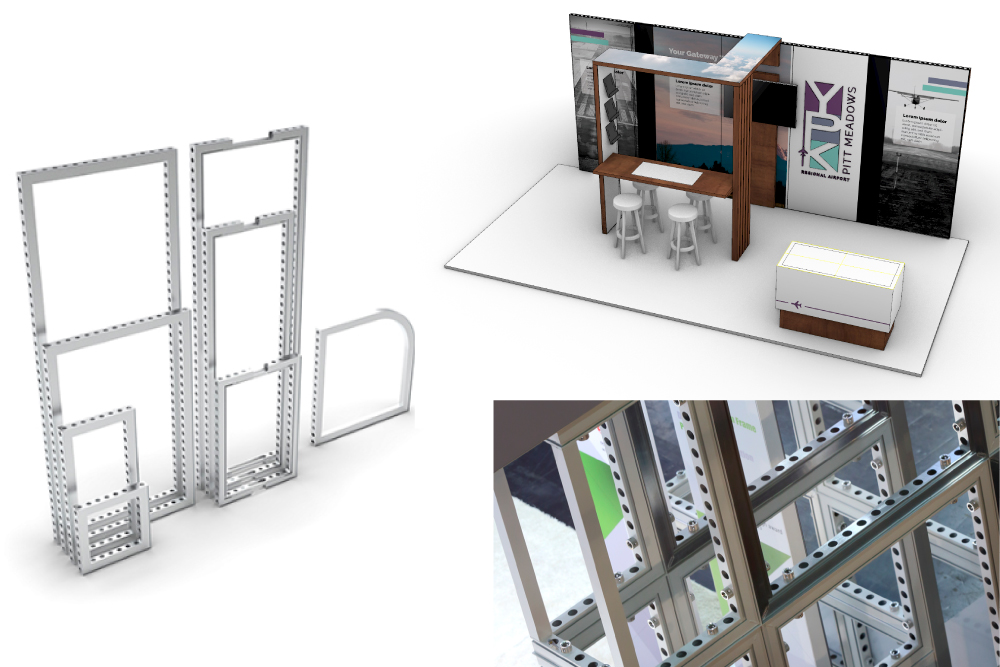

Modular exhibits are built using extrusion frame systems—pre-engineered aluminum parts that can be mixed, matched, and reconfigured to suit your layout needs. Think of it like a beefed-up LEGO set. These systems are lightweight, reusable, and easy to set up.

Two of the most common systems we use are:

beMatrix

beMatrix frames come in standardized shapes that form the backbone of your display.

- Lightweight aluminum frames

- Fast setup and teardown

- Accepts Velcro-applied graphic panels or fabric SEG (silicone edge graphics) for a sleek, seamless look

- Backlight-friendly for eye catching visuals

- Hardware with minimal visibility

Octanorm

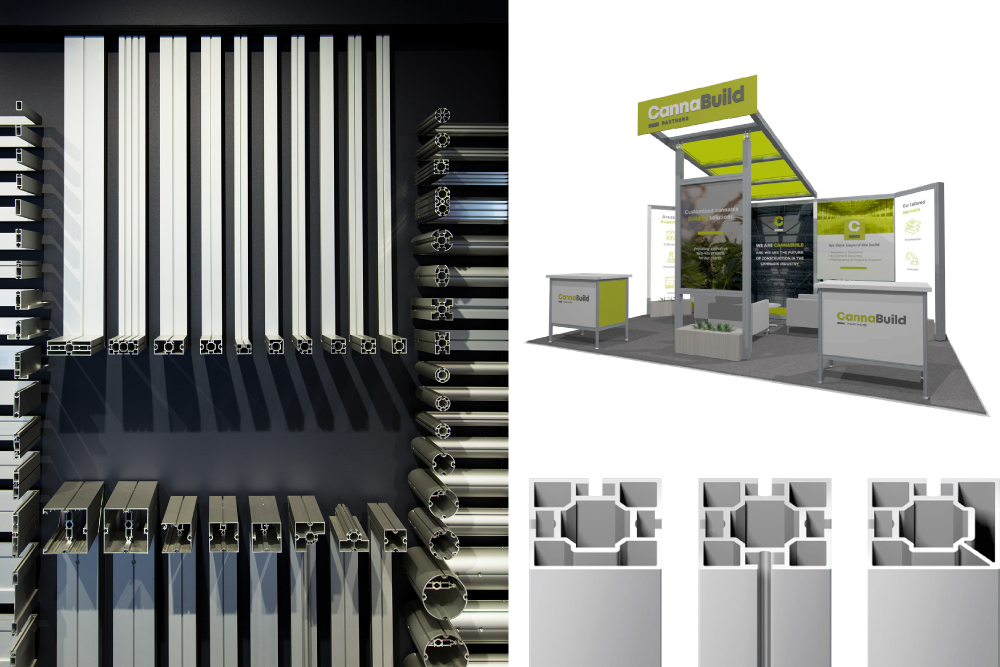

Octanorm is another popular system known for its versatility.

- Wider variety of shapes and sizes for extrusion pieces that connect to create frames

- Accomodates rigid panels and fabric graphics, along with backlighting

- More hardware visibility, but greater flexibility with configurations

Modular systems are excellent for brands that exhibit frequently, need to adapt to different booth sizes, or want a clean, modern look with easy transport and storage.

Custom Exhibit Frames: Built From the Ground Up

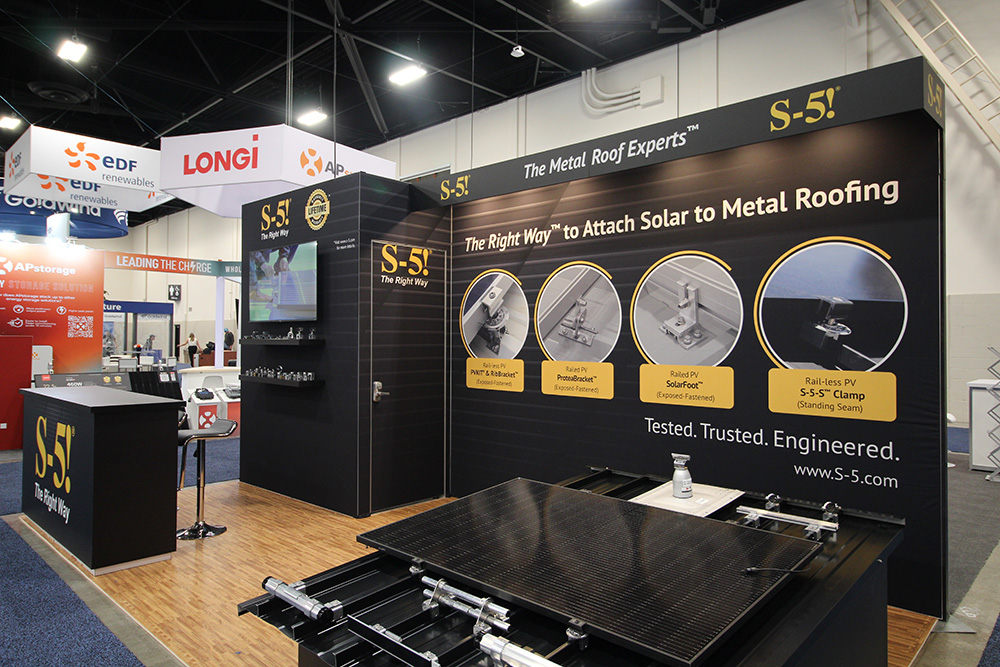

Custom exhibits don’t rely on any standardized frame systems. Instead, everything is designed and built from scratch from a broader range of materials. Modular displays can absolutely look custom—with tailored graphics, signage, finishes, and accessories—but what sets a true custom build apart is the unique framework underneath. Custom booths typically use wood or metal substructures, allowing greater freedom in shape, size, and creative detailing.

Materials used in Custom Booths

- Wood framing (MDF, plywood, or solid wood) for walls, canopies, and other features

- Metal supports or accents for structure and aesthetics

- Acrylics, laminates, and specialty finishes for high-end surfaces

- Custom millwork for integrated shelving, product displays, or demo areas

This approach gives you full control over the architectural feel of your space from ultra-modern, to rustic, to luxury retail-inspired environments.

Graphics: Modular vs. Custom

No matter the booth style, great graphics are essential. Here’s how the materials and mounting methods differ:

Modular Exhibit Graphics

- Fabric SEG: the material is either stretched over the frames for a seamless look, or set between the frames

- Rigid graphics panels: typically printed on materials like PVC or laminated foam core, these mount directly onto the frame

- Backlighting: Both SEG fabric and select rigid materials can be backlit with LED panels

Modular graphics can be easily updated without changing the hardware, making these systems cost-effective for multiple shows.

Custom Exhibits

- Printed directly onto wood, acrylic, metal, or specialty materials

- Can include dimensional signage, cut vinyl, or 3D elements

- Allows for non-conventional shapes, curved surfaces, or themed textures

- Often incorporates high-end finishes like gloss, matte, brushed metal, or woodgrain laminates

Because the materials are more varied and the construction is unique, custom booth graphics offer far more creative freedom but they also typically require more time and budget.

Which Type of Exhibit is Right for You?

It all comes down to your brand’s needs, goals, budget, and how often you’re hitting the trade show circuit.

Go Custom if You:

- Have a unique, show-stopping vision

- Need one-of-a-kind shapes, structures, or finishes

- Exhibit at high-end or design-driven trade shows

- Require integrated technology, custom meeting spaces, or specialty build-outs

Keep in mind: custom booths involve higher costs for fabrication, shipping, install/dismantle, and storage. They also take longer to build and require more coordination.

Modular is great if you:

- Exhibit frequently or at multiple shows with different booth sizes

- WaWant a lightweight, easy-to-set-up solution

- Need to reconfigure or update graphics often

- Want to balance clean design with efficiency and cost control

Hybrid Booths: The BEst of Both Worlds

Many of our clients choose to go with a hybrid approach: a modular aluminum structure for the base, with custom add-ons like wood features, branded counters, or specialty lighting. This gives you flexibility and ease of transport, with just the right touch of custom flair.

Custom or Modular Exhibits: Still Not Sure?

That’s what we’re here for. Whether you’re starting from scratch or evolving an existing display, we’ll help you choose the right solution for your goals and budget – custom, modular, or somewhere in between.