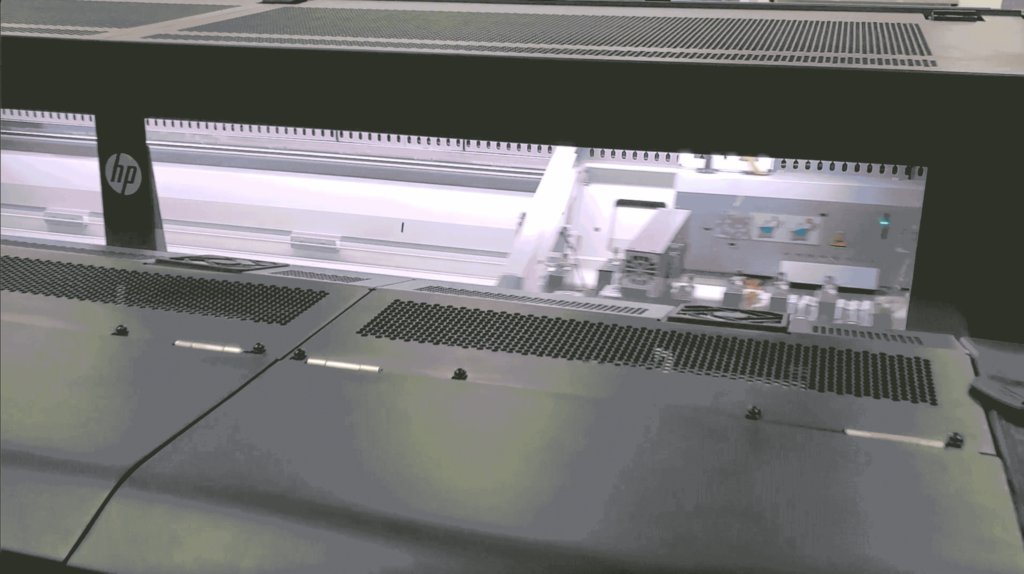

It’s officially happening, and it’s been a long time coming. After several months of research, attending webinars, and visiting all the different models we could in person, we are finally adding a flatbed printer to our team! So in a couple of weeks, we’ll have the new HP Latex R1000 Flatbed Hybrid Printer here with us in the shop. It’s going to be like having a celebrity join the crew as I know I’m going to fangirl over it a bit, and I can guarantee that Tyler will be fanboying as well. Getting this new printer isn’t just simply getting a new piece of equipment, but the new technology will allow us to expand our capabilities and bring in new kinds of work that weren’t available to us before.

Until now, when we needed a print on something rigid, we would print onto a roll of decal (self-adhesive vinyl) and then mount the decal to the stiff material afterward. We did this because our current printer is solely a roll-to-roll style, and a material like Sintra would in no way wrap itself around a roll. This process included an extra step and limited the kinds of print jobs we could achieve because we couldn’t print directly onto the material itself. Roll to roll is by no means a flawed printing method, and we’ll still use it for multiple kinds of jobs. The hybrid function of this new model means that it can print roll to roll in addition to the flatbed style rigid prints. What a multitasker.

And so, enter the celebrity!

With this new tech, we’ll be able to print directly onto surfaces such as Sintra, ACM, Foam Boards, Acrylic, and Glass, to name a few. This model also has white ink, which we’ve never had before. In addition, because it has a roll-to-roll option, we’ll be able to get that white ink onto roll materials like window graphics to create privacy patterns on transparent materials, for example. The way you can print on things like Plexi or glass is really unique, gives a sense of dimension, and adds personality to your piece. The capabilities that this hybrid model provides are the best fit that we could find for the types of projects that we would like to be doing here at Exhibit Studio.

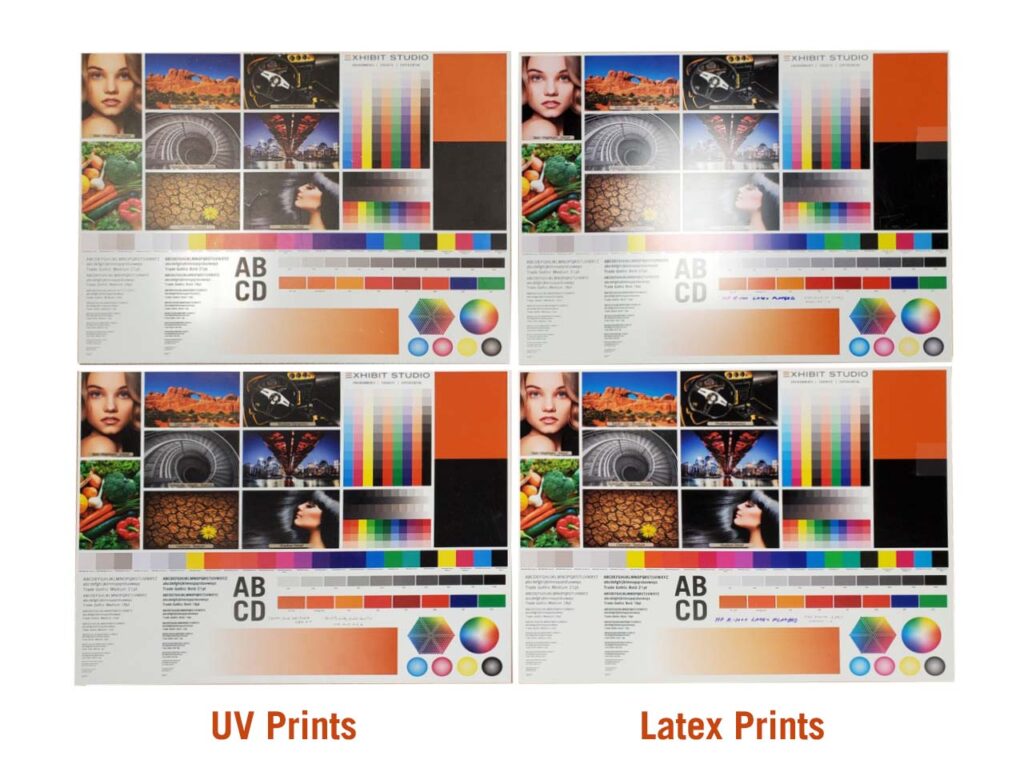

The prints that come out of this machine are sharp and clear with vibrant colours, thanks to HP’s latest printhead technology. It also has a durable ink that doesn’t scratch as easily as other flatbed printers we tested. Trust us when we say that we’ve compared the print quality of MANY different styles of printers. We’ve got literal stacks of printer samples from our time shopping around and below are some of the test prints that we’ve conducted on different machines.

Our new printer uses eco-friendly Latex inks and won’t smell bad like most UV flatbed printers. We are very excited that it won’t be stinking up our office too. Water-based inks that don’t use solvents will give our clients greener options that they can feel good about.

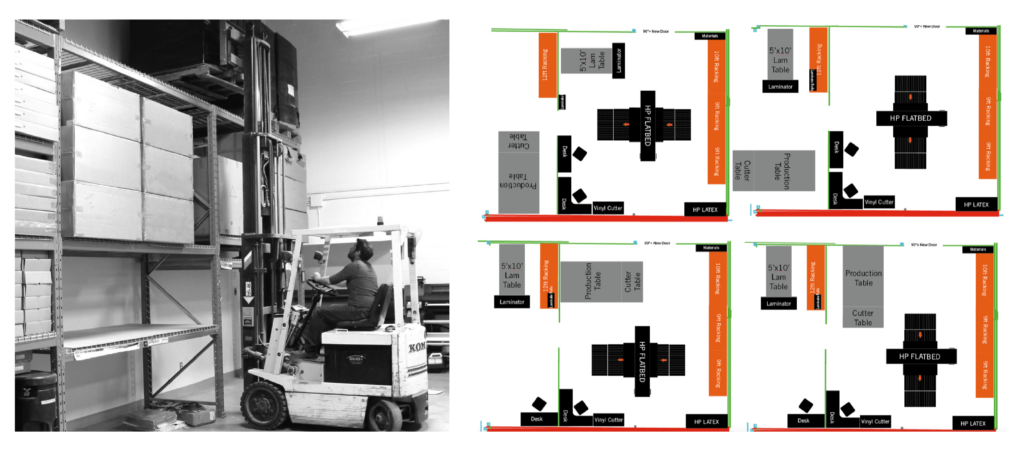

There has been a lot involved to prepare for this thing. Tyler pre-planned layouts of equipment and has reorganized the entire print production area. We installed a larger door so that the printer and all the materials it uses can fit into the space more efficiently. We’ve also had to rethink how the power is distributed throughout our workspace and ensure it has enough juice to function. Almost all our prep work is complete, and we’re patiently waiting for it to come through the doors. Now it’s time to research and find the best materials for direct printing, so we can give you the best quality possible while still being affordable.

Tyler is very much looking forward to operating the new flatbed. He has experience with printers like these and worked with one for two years at Quintaro Imaging. He is ready to develop new processes and ways of doing things, which will keep him on his toes for quite some time. There are exciting things on the way for the team at Exhibit Studio, and we hope you stay tuned to see what fun new ways of doing things we’ll come up with!