Ever wonder how the stainless steel engravings on your coffee tumbler are made? Or how perfectly shaped 3D lettering appears on your vehicle? Chances are it was made using a laser! In December we acquired a new flatbed laser and have been having fun exploring new projects with its versatile capabilities. If you’ve ever been curious about how one of these machines works, we’ll explain in this article.

What exactly does a laser do? The first thing that comes to mind might be lightsaber battles, or obstacle courses that spies must weave through in the movies. While those are all very exciting, lasers have a much more practical use here at Exhibit Studio for display design.

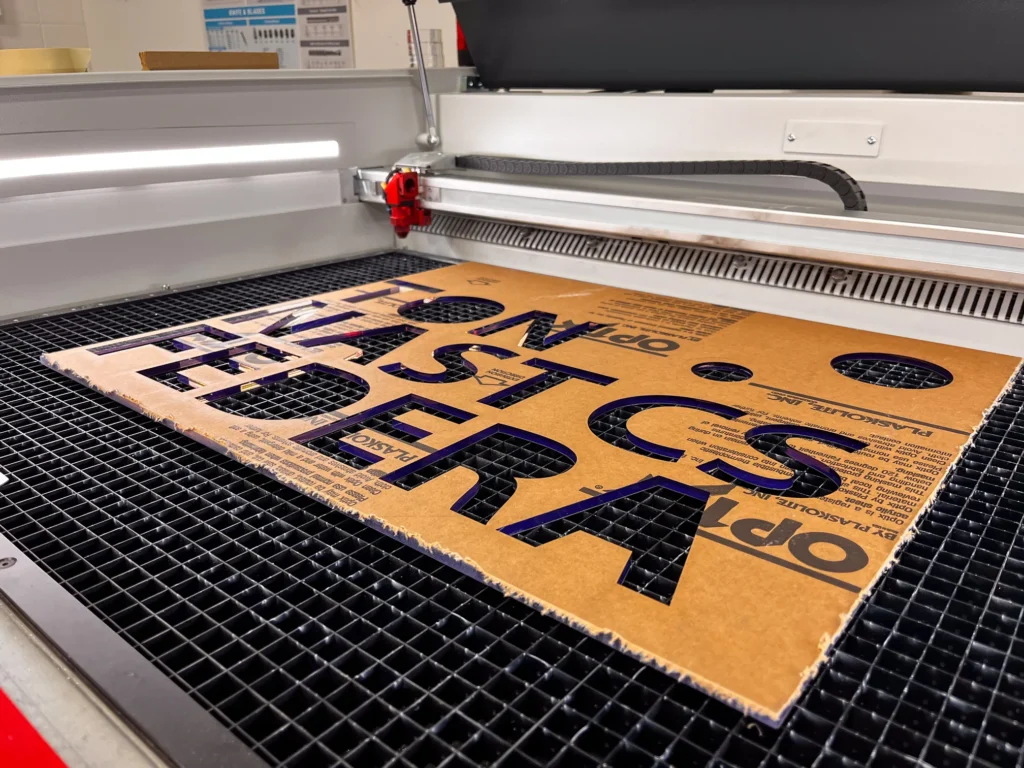

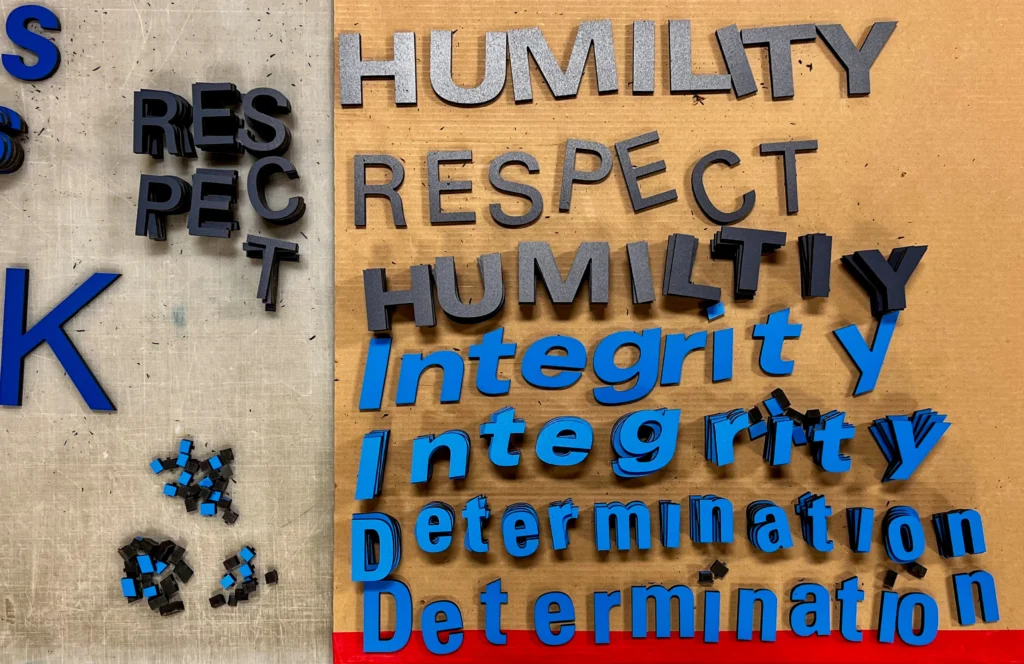

The flatbed laser that we use in our studio can cut, mark, engrave, and etch a wide variety of materials to make fine letters, shapes, and other intricate patterns. Each of these processes is different to achieve a certain result. The laser uses carbon dioxide to generate a high power output for cutting fine features. It’s great for logo signage and is the fastest laser engraver machine on the market with the best contour accuracy.

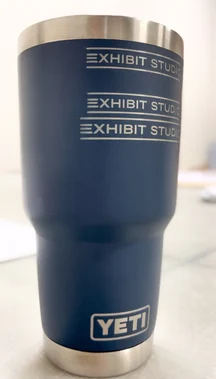

Laser engraving is the process where high heat is used to vaporize and remove from the surface of a material to create an indent. Take this Yeti mug for example. The engraved areas are where the blue parts have been removed to reveal the stainless steel pattern below.

Laser etching is a type of engraving. The difference is that etching adds a deposit rather than subtracting from it. For example, if you were etching a stainless steel tag, a special kind of paint would be deposited across the entire tag. Then when the residual is cleared using a chemical process and heat, it leaves behind the lettering/design in the paint.

Laser marking adjusts the appearance or properties of a material without leaving a cavity or raised surface, unlike engraving and etching. This results in discolouration and contrasting marks.

In our studio, we have our new laser flatbed as well as a larger CNC router machine. CNC stands for computer numerical control. Rather than someone having to manually cut into materials, the machine follows computer-coded instructions programmed by the operator to create the design. While our CNC can take on larger projects than the laser flatbed, the new machine has quite a few advantages.

One is that the flatbed is significantly quicker and more accurate. It can achieve things the CNC cannot, such as tiny designs down to a 2-point font. The laser creates high-quality flame-polished edges, whereas the CNC products require further finishing. From wood to glass, rubber, plastic and more, the new laser can process anything with just a couple of mouse clicks.

From signage to exhibits and creative projects, we’re thrilled to have this piece of equipment in our studio to expand our trade show design creative capabilities.